Electrofusion Welding Materials

Electrofusion Welding Machine: These are the machines produced under computer control. The controls of the machine are provided by microprocessors.

The welding information of the fasteners is entered into the machine with barcodes or manually. The minimum working intervals of the welding machine and the welding information that should be seen on the screen are as follows;

• Input voltage: 185-285 V

• Output voltage: 8-48 V

• Frequency: 35-70 Hz

• Current : AC (ALTERNATE CURRENT)

• Power: 2.8 -4 kW

• Duration(time): seconds(s), minutes(min.)

• Resistance:Ohm(Ω)

• Ambient temperature: °C

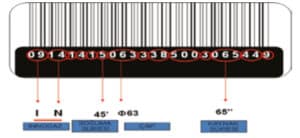

Barcode: Required information about the object it belongs to by hovering with special devices.

is the line code or bar code from which information can be obtained. With these codes on the connection piece, the welding information is taken by the machine and the welding

settings are made automatically.

Safety Strip: Excavated for pedestrian and vehicle safety, life and property safety

It is generally painted in red/white color, 5-10 cm wide, 200-

They are plastic-based tapes used in rolls of 500 meters.

Indicator: The mark is the connection part used in Electrofusion welding.

protruding marker on it, indicating that melting has occurred.

POLYETHYLENE PIPE WELDER

Scraper (rasp): While producing polyethylene pipes, ultraviolet rays,

The outer surface is covered with oxidized polymers in order not to be adversely affected by the changes in hot-cold ambient conditions. The tools used to clean the oxidized layer are called pipe scraping apparatus or pipe scraper.

According to the method of pipe scraping, pipe scrapers are divided into two as Hand Type and Mechanical. In general, hand-held pipe scrapers are used. Hand-held pipe scrapers consist of a cutting metal blade that can be mounted on a wooden body. The cutting blades can be disassembled, replaced and even sharpened. However, it is not desirable for the scraper blade to be excessively sharp.

PE Pipe Cutters:

Type: Ø 20/32 mm and Type: Ø 63/110 mm.PE pipe cutters

main parts; a cutting edge, concave seating surface suitable for the fitting of the pipe outer surface, stepped

For the smooth continuity of the tightening process

step lever fixing plate, two opposing articulated arms to which we apply the clamping force, and movable to keep these arms tight when not in use.

consists of a ring.

Guillotine shears, with a body with bearings in which the cutter blade can move, and an opening and closing mechanism that allows full centering of the pipe.

It consists of a hinged V-piece that can be closed.

Make sure the guillotine moves up or down.

It works with the help of a nut-screw system that provides a circular motion and a lever that allows this system to make circular movements.

POLYETHYLENE PIPE WElder

Poly-stopp: It is a special tool for performing operations such as branching, displacement, line cancellation and drilling and plugging without cutting gas on the polyethylene network.

is equipment. It is used in lines with 110 and 125 mm diameters.

Positioner: It is the equipment used for easy welding of the parts that are thought to be joined during the welding operations on the PE network, mounting the connection piece and fixing the position given before welding until the end of the cooling period.

Positioning: It is the fixing of the connection piece material with the help of a positioner before electrofusion welding in order to ensure that the cutting surfaces of the pipe parts kiss and to prevent the tensions that may occur during the cooling phase after the electrofusion welding (contraction in the pipe).

Solvent: Used to dissolve binders or thin some liquids.

volatile liquid, solvent, solvent. in a solute dissolved in a solution

liquid or gaseous medium in which it disperses and forms a homogeneous mixture. Solvent

The purpose of using it is to remove dirt, oil, dust, etc. in the welding area. cleaning items. The solvent must be self-volatile (toulen and naphtha)

type may be).

Spool: It is the combination of more than one material (pipe, valve, tee, etc.) with welded manufacturing.